Ultimately, the ends being turned to ¼” was not that big of a deal, as so many motor couplings are available which will do the adapting for you, but, live and learn. ½-10 threads and turned to 1/4” on the ends for a motor coupling. I liked how they produced a lead screw tailor made for the home CNC market, i.e. My very first purchase was 3 precision lead screws from Precision Tech Machining LLC in Florida. There are a lot of manufacturers of both, and commonly available on Ebay.

I first started with the axis movement components, i.e. I’m not going to get into the details of where I purchased everything(I doubt you care I bought 3 misc screws at Home Depot), but will try to set you on the right path for the major components. I figured the software/computer part was easy, so I would save that till the end(I was wrong BTW), and started sourcing the main components online.

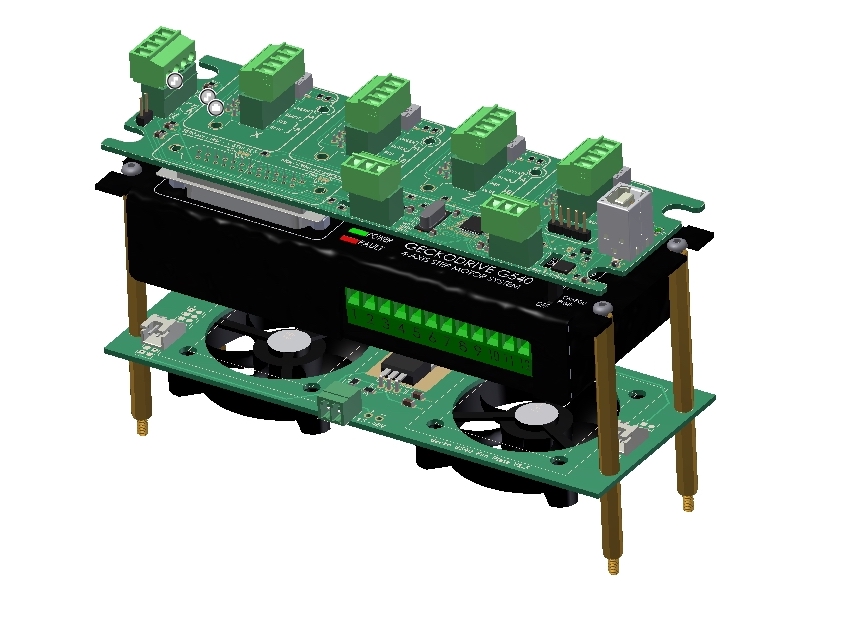

GECKO G540 FAULT LIGHT SOFTWARE

Their price(with shipping) was comparable to the Probotix unit, but I was concerned if the unit ever had a problem, that I would basically be dealing with no support, so, that was the final nail in the coffin for a commercial unit, as they start getting exponentially more expensive as you start getting above the units I described above.Īfter all my research, all I really knew was that I needed 3 axis’s, some motors to drive them, a computer to control them, and some software to design the parts. Next, I looked at a couple of similarly sized units available on Ebay, mostly from China. I was all set to order the Probotix Fireball V90, but just couldn’t accept the lack of true linear bearings and standard(non-anti-backlash) nuts in the base model, so that one was off the table. Of course now, I know the feed speed is dictated by the machine controller, but, I’m still glad I decided to go off and try on my own anyway. Not knowing much about how the systems worked at the time, I decided against the Zen unit as I didn’t like the speed the machine ran at in the videos I could find. My very first steps were looking at the low end commercially available units, primarily those from Zen Toolworks and.

The idea being that a computer can control a cutting bit far more precisely than a human can, but, I suspect if you’re reading this article you’re already familiar with the concept, so I’ll go on. For those not familiar with the term, CNC stands for Computer Numerical Control. IT’S AN ARTICLE I HAD ON A DEFUNCT WEBSITE I JUST WANTED TO KEEP SOMEWHEREĪ couple months ago, I decided I had it in me to have a go at building my own CNC machine. We will contact you as soon as your drive has been evaluated and if there are any questions from our engineering team.THIS IS A LEGACY POST THAT HAS NOTHING TO DO WITH POINTS AND MILES. Some repair charges may apply to drives out of warranty and those with customer induced damage.

GECKO G540 FAULT LIGHT FREE

All drives still covered under warranty are evaluated and repaired free of charge if there is no board-level damage and include free return shipping within the USA. Most product returns take around 5 business days but may take longer depending on workload. Please follow this link and complete the form to receive an RMA number. If you do, then you will want to plug each G250XR3 in individually (powering off while plugging them in) and seeing if you get a green LED with each one.Įventually, you will find one that is causing the motherboard to go into FAULT. When you find that one you can send it back to us for evaluation and repair.

Plug it in the same way as previously described and see if you get a green LED. If the red LED stays on regardless of the setup then I would recommend taking the cover off and removing the motherboard from the G250XR3 drives inside. A reading of zero ohms (or close to that) means it is okay a reading of an open circuit means it has blown and should be replaced. It will be socketed to allow for easy removal, and all you need to do is test it with an ohmmeter.

The fuse will be located on the motherboard near TERMINALs 11 and 12 and will look like a green 1/4W resistor. Should no LEDs turn on you will need to remove the cover and check fuse continuity. If you do, begin plugging in your motors one by one to see if the problem is emanating from one axis. With only those things done you should get a green LED. The easiest way to check to see if the Geckodrive G540 is working correctly is to connect only your power supply, a jumper wire between TERMINAL 10 and 12 and turn off the charge pump switch on the front of the drive.

0 kommentar(er)

0 kommentar(er)